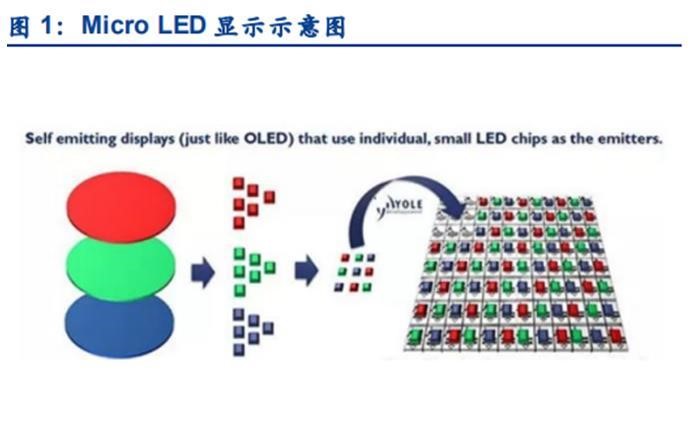

MicroLED is a type of light emitting diode (LED), typically less than 100μm in size. Common sizes are less than 50 μm, and some are even as small as 3-15 μm. In terms of scale, MicroLEDs are about 1/100 the size of conventional LED and about 1/10 the width of a human hair. In a MicroLED display, each pixel is individually addressed and driven to emit light without the need for a backlight. They are made of inorganic materials, which provide a long service life.

The PPI of MicroLED is 5,000 and the brightness is 105nit. The PPI of OLED is 3500, and the brightness is ≤2 x 103nit. Like OLED, the advantages of MicroLED are high brightness, low power consumption, ultra-high resolution and color saturation. The biggest advantage of MicroLED comes from its biggest feature, the micron-level pitch. Each pixel can address control and single-point drive to emit light. Compared with other LEDs, MicroLED currently ranks high in terms of luminous efficiency and luminous energy density, and there is still room for improvement. It's good for flexible LED display. The current theoretical result is that, comparing MicroLED and OLED, to achieve the same display brightness, only about 10% of the coating area of the latter is required. Compared with OLED, which is also a self-luminous display, the brightness is 30 times higher, and the resolution can reach 1500PPI, which is equivalent to 5 times the 300PPI used by the Apple Watch.

Since MicroLED uses inorganic materials and has a simple structure, it has almost no light consumption. Its service life is very long. This is incomparable with OLED. As an organic material, OLED has its inherent defects-lifespan and stability, which is difficult to compare with QLED and MicroLED of inorganic materials. Able to adapt to various sizes. MicroLEDs can be deposited on different substrates such as glass, plastic, and metal, enabling flexible, bendable displays.

There is a lot of room for cost reduction. At present, the micro-projection technology requires the use of an external light source, which makes it difficult to further reduce the size of the module, and the cost is also high. In contrast, the self-illuminating MicroLED microdisplay does not require an external light source, and the optical system is simpler. Therefore, it has advantages in miniaturization of module volume and cost reduction.

In the short term, the Micro-LED market is focused on ultra-small displays. In the medium and long term, the application fields of Micro-LED are very wide. Across wearable devices, large indoor display screens, head-mounted displays (HUDs), taillights, wireless optical communication Li-Fi, AR/VR, projectors and other fields.

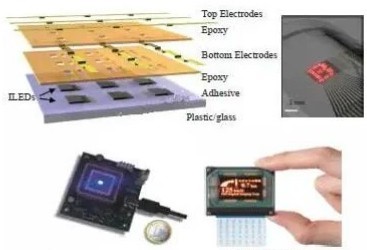

The display principle of MicroLED is to thin, miniaturize and array the LED structure design. Its size is only about 1~10μm. Afterwards, the MicroLEDs are transferred to circuit substrates in batches, which can be rigid or flexible transparent or opaque substrates. Transparent LED display is also good.Then, the protective layer and the upper electrode are completed by the physical deposition process, and then the upper substrate can be packaged to complete a MicroLED display with a simple structure.

In order to make a display, the surface of the chip must be made into an array structure like an LED display, and each dot pixel must be addressable and controllable and individually driven to light up. If it is driven by a complementary metal oxide semiconductor circuit, it is an active addressing driving structure, and packaging technology can be passed between the MicroLED array chip and the CMOS.

After the paste is completed, the MicroLED can improve the brightness and contrast by integrating the microlens array. The MicroLED array is connected to the positive and negative electrodes of each MicroLED through vertically staggered positive and negative grid electrodes, and the electrodes are energized in sequence, and the MicroLEDs are lit by scanning to display images.

As an emerging link in the industry chain, Micro LED has a difficult process that other electronics industries rarely use—mass transfer. Mass transfer is regarded as the core factor affecting yield rate and capacity release, and it is also the area where major manufacturers focus on tackling tough problems. At present, there are different directions on the technical route, namely laser transfer, self-assembly technology and transfer technology.

What kind of technology is "mass transfer"? To put it simply, on the TFT circuit substrate the size of a fingernail, according to the necessary specifications of optics and electricals, three to five hundred or even more red, green and blue LED micro-chips are evenly welded.

The allowable process failure rate is 1 in 100,000. Only products that achieve such a process can be truly applied to products such as Apple Watch 3. Surface mount technology has now achieved mass transfer technology production in MINI LED, but it needs practical verification in MicroLED production.

Although MicroLED displays are very expensive compared to conventional LCD and OLED panels, their advantages in brightness and energy efficiency make them an attractive alternative in ultra-small and very large applications. Over time, the MicroLED manufacturing process will allow suppliers to reduce production costs. Once the process reaches maturity, MicroLED sales will begin to rise. To illustrate this trend, by 2026, the manufacturing cost of 1.5-inch microLED displays for smartwatches is expected to drop to a tenth of the current cost. At the same time, the manufacturing cost of a 75-inch TV display will drop to one-fifth of its current cost over the same time period.

In the past two years, the Mini Led industry will quickly replace the traditional display technology. In 2021, the electronic display industry such as vehicle display, home appliance display, conference display, security display and other electronic display industries will launch a general attack and continue until the Micro LED mass production technology is stabilized.

Post time: Oct-21-2022