The development potential of the Mini LED backlight market is huge, and packaging manufacturers are accelerating their deployment. At this stage, in order to accelerate the market penetration of Mini LED backlight, it is necessary to strike a balance between cost and technology, so the choice of packaging technology is particularly important.

As a leader in China's LED packaging and backlight packaging industry, Nationstar has taken the lead in deploying the Mini LED backlight field, continuously strengthening key technology research and transformation of scientific and technological achievements, and promoting the development of new display commercialization with forward-looking technologies.

The market size of Mini LED backlight in TV/MNT/NB/PAD and wearable VR is growing. It is expected that by 2025, Mini LED backlight TV will occupy half of the high-end TV market. It can be used in flexible display. With the penetration of high-end MNT for e-sports and creators, the penetration rate of Mini LED backlight MNT will increase to 6%. In the field of small-size PAD/NB applications, Apple is the first to use Mini LED backlighting on iPad Pro, which acts as a wind vane for the entire industry. The penetration of Mini LED backlight in the PAD field in the future is expected to maintain healthy growth. Since this year, major brands have successively released new products of Mini LED backlight NB, embarking on the road of commercialization.

In addition, in the field of vehicle display and wearable display, due to the issue of vehicle certification cycle, vehicle Mini LED backlight display was not mass-produced and shipped in the first two years. It is expected to start to emerge this year, and the volume will begin to increase in the next two years. With the rise of the concept of "metaverse", VR has also begun to be sought after by capital and consumer electronics concepts, and more and more VR headsets have begun to be equipped with Mini LED backlights.

To sum up, it can be seen that the application scenarios of Mini LED backlight are diverse, the market volume continues to rise, and the development prospects are relatively broad.

However, affected by the new crown epidemic and the complex and changeable international situation, the terminal price war has intensified, and the global shipments of Mini LED backlight products are still lower than expected. Then, as the competition in the Mini LED backlight industry has entered a white-hot stage, which of the POB and COB packaging technologies can better meet the needs of the market and release volume? Are the two alternatives or coexistence?

The mainstream packaging forms of Mini POB are TOP bracket type, Cake type and CSP type. The main process is based on the traditional packaging process of "die bonding - wire bonding (positive installation) - packaging - testing and sorting". The main materials include chips, brackets & substrates, gold wires & solder paste and packaging glue, which are not much different from traditional packaging processes. It is also used in transparent led display. Through the unique light source structure design, Nationstar photoelectric enables light to be emitted within a large viewing angle range to meet the needs of thin, light, high-quality and low-cost display modules. Under the same backlight module, the number of lamp beads required is greatly reduced, optimizing The cost of the backlight is very high, and the mass production yield is very high.

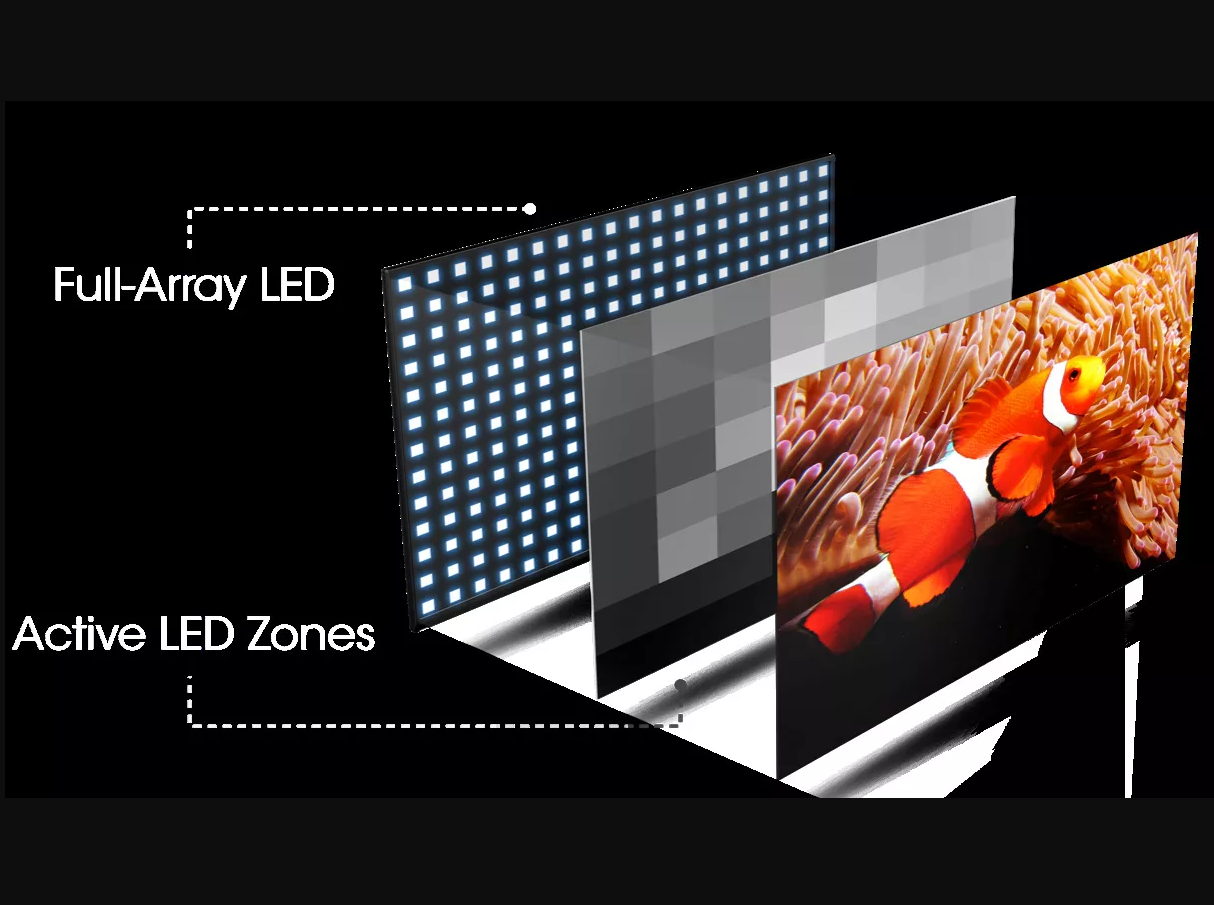

According to reports, the early lamp driver separation technology is simple and easy to produce; later it gradually developed into PM type lamp driver integration technology, which has a high degree of integration and is conducive to the thinning of backlight modules; and then developed to AM-Micro IC type The light-drive integration technology is conducive to the realization of high partition count design, and the local dimming visual effect is more prominent. Mini POB has low process difficulty, low cost investment, high module yield and strong mass production, but limited by the package size, it is widely used in large OD modules, mainly for low-end TV, MNT and automotive markets.

Different from Mini POB, Mini COB is a chip-level mounting solution, which proposes higher technology for key processes such as printing, die bonding, rework and packaging, as well as materials and equipment such as PCB, chip, packaging glue, jig & equipment Require. In terms of performance, Mini COB develops in the direction of high brightness, high consistency, high reliability and high cost performance. In order to achieve better performance, National Star photoelectric adopts full-array high-efficiency chips + package lightening treatment to solve the problem of insufficient screen brightness; through special die bonding algorithm combined with package optimization, it solves the problem of uneven brightness and spots on the screen; withstand high temperature and high humidity and cold punching experiments to ensure high reliability; optimize the cost of the light source, so that the price of the module reaches an acceptable level for the consumer side.

In terms of packaging technology, Nationstar photoelectric uses a highly reliable flip-chip LED chip with an optical lens package to form a large light-emitting angle to meet the needs of medium and large size TV/MNT display modules for thinness, high image quality, and low cost; at the same time, through Pitch 2.0mm dense chip light source and integrated packaging technology make the OD close to 0mm, which can be applied to ultra-thin terminals such as PAD/NB. Such as P1.56 flexible display. At present, Mini COB has high process difficulty, high cost investment and low module yield. In the future, with the improvement of technology maturity in each link of the industry chain, the yield rate will be solved. Its development prospects are far greater than that of Mini POB. Cosmic, high-end atmosphere display decoration and other applications in all fields.

With the increasing diversification of Mini LED backlight terminal products and the increasing market acceptance, the competition in the Mini LED backlight industry has gradually intensified. Under this circumstance, Nationstar has integrated the original Mini LED backlight segment into the component business department to integrate talents, customers and supply chain resources, better focus on Mini LED backlighting, and provide Mini LED devices and Mini LED backlight modules. At present, Mini POB is still the mainstream of the market until 2025. It is more suitable for 43-85-inch TV, 17-39-inch MNT and vehicle display, and has the highest cost performance overall. Mini COB is more suitable for 13-16-inch NB , 8-12.9-inch PAD, single-board products are conducive to improving yield and reducing costs.

With the continuous maturity of the production process and the increasing level of technical equipment, Mini COB will become the mainstream of the market after 2025, and Mini POB will gradually abdicate at that time.

Post time: Nov-02-2022